Electrostatic charges can cause a number of issues during textile production, such as dust attraction, shocks, sparks etc. These in turn can lead to potentially hazardous situations due to discomfort to operators and even fires, as well as annoyances such as frequent interruptions in production due to stoppages, reduced sliver/yarn evenness, quality issues on yarns and fabric etc. Hence, such bothersome electrostatic charges need to be neutralised. To address these problems, Valence offers many solutions for measurement and removal of static charges.

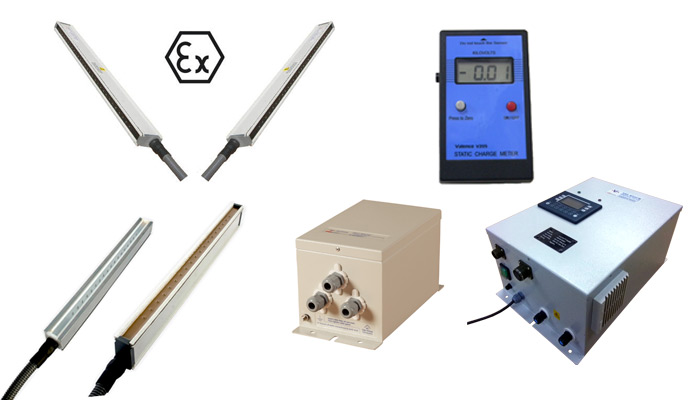

Valence provides a range of electrostatic control solutions:

1. Active static charge eliminators: These bars have a row of electrodes across the active length. Positive ions are produced during the positive half cycle and negative ions during the negative half cycle of the power supply. These ions neutralise the charges of opposite polarity on a fast moving target.

2. Static charge monitoring: The magnitude and directions of the electrostatic charges need to be measured for taking the most effective preventive measures. Valence’s static charge meter is a compact, highly sensitive electrostatic surface voltmeter which is designed to locate and measure surface voltage on stationary and moving objects, people and equipment. It measures both the magnitude and polarity of charges.

3. Electrostatic charging: A Valstat® charging electrode and high voltage (HV) generator together provide a compact, sturdy, and efficient system for generating electrostatic charges for localised and linear charging applications.

Valence’s range of electrostatic control solutions is suitable for textile applications such as:

1. Carding: During carding, an oscillating comb or rotary brush combs or a roller take off fibre from the doffing cylinder. This process creates a large amount of static on the fibres, resulting in them clinging at the receiving part and in the delivery section. Static charges can reduce machine speeds and result in frequent stoppages which result in loss of productivity. This can be easily prevented with Valence’s Valstat® active static eliminating bars.

2. Warping: In warping, static charges are generated on yarns and filaments due to unwinding and separation of fibres from the bobbins while passing through (contact) and coming out (separation) of the eyelets and combs. The machine has to be then slowed down to avoid breakage of the yarn or filament, poor warping, and overlapping of the yarn or filament on the warp beam. Valence’s Valstat® active static eliminating bars will enhance productivity by effectively neutralising the static charges on the fibres.

3. Beam sizing: Static charges are generated on the yarn in the sizing process. This result in operator hazard, adhesion to the rollers, contamination, web wander, etc.

4. Batching and plaiting: During the batching or plaiting processes on a stenter and other fabric processing machines, static charges are generated on the fabric due to contact and separation of fabric from rolls and changes in temperature. Excessive static charges on fabrics cause the fabric to adhere to the rollers, web wander, and dust attraction, improper plaiting, etc. These issues can be addressed by the Valence’s Valstat® active static eliminating bars.

5. J scrays etc: Valstat®antistatic bars eliminate issues like adhesion of fabric to rollers, operator hazard, dust attraction, etc., in the J scrays of stenters, drying ranges, printing machines, sanforisers, or mercerisers.

For creating controlled levels of electrostatic charges in certain textile processes, Valence offers electrostatic charging electrodes powered by high voltage (HV) DC charging generators.

6. Flocking: Through a rotary flock hopper, flocks fall freely onto a fabric. This results in the clogging of flocks and an uneven layer of the fibres on the fabric, eventually leading to rejection. The Valence Valstat® HV charging generator creates a controlled high voltage that is supplied to the grid. This HV induces the appropriate electrostatic charges to the flocks and orients the flocks perpendicularly when they fall. This ensures a dense and pile-like finish.

Apart from these, Valence’s electrostatic control solutions can be effectively used in other textile applications such as peaching machines, fabric inspection and folding machines, compacting machines, draw frames, and others.

Ashok Sethuram, Director, Valence Electrons, said, “A.T.E.’s presence in the textile market for over eight decades has helped to build a close and constant connect with OEMs and end users. It enables us to better understand customer requirements. This learning in turn has given an impetus to our product development efforts. We have a strong hardware and software development team working closely with application specialists, who ensure that a ‘close fit’ solution is found for improving productivity, safety and quality. We are proud to say that all our products are not only manufactured but also designed in India, ensuring high quality import substitutes at affordable costs. Also, our pan-India after-sales service team provides prompt service. We are an ISO 9001:2015 certified organization and work towards continual development. The textile industry in India has evolved, and is forever on the lookout for thoughtful and sophisticated engineering to compete effectively at a global level. In addition, safety, health and environment concerns are getting more and more important.”

Headquartered in Bengaluru, India, Valence Electrons is an A.T.E. Group company that provides world-class indigenous solutions for managing static electricity, ink handling, surface cleaning, and heat recovery in various industrial applications. Valence Electrons’ is committed to providing innovative, customer-driven, and cost-effective solutions to the Indian textile industry for improving productivity, safety and quality.