The Indian textile and apparel industry is rapidly innovating to meet the specific requirements of the markets across the world. Furnishing, upholstery, shirting and suiting with multicolour, multi-material or mono colour fabrics are either required in small production batches and/or with actual fabric width to make full garment. Sample fabrics are required in even shorter lengths and within the shortest possible time due to customer centric market requirements. Manufacturers need to be on their toes to quickly cater to premier customers and grab orders to retain their market share.

The Indian textile and apparel industry is rapidly innovating to meet the specific requirements of the markets across the world. Furnishing, upholstery, shirting and suiting with multicolour, multi-material or mono colour fabrics are either required in small production batches and/or with actual fabric width to make full garment. Sample fabrics are required in even shorter lengths and within the shortest possible time due to customer centric market requirements. Manufacturers need to be on their toes to quickly cater to premier customers and grab orders to retain their market share.

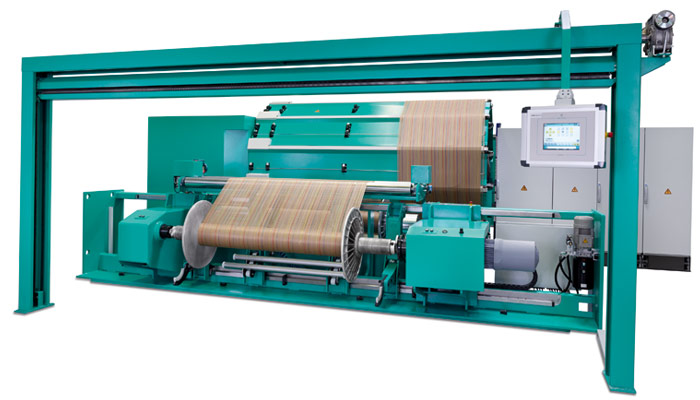

KARL MAYER – innovator and manufacturer of world class technology products across the entire warp preparation range –has introduced the state-of-the-art MULTIMATIC to produce sample short and medium length warp beams. The key advantage of the MULTIMATIC is its ability to produce warp beams with required warp colour patterns within the shortest time.

MULTIMATIC is available in 3 executions, MM128 (with 128 bobbins), MM64 (with 64 bobbins) and MM32 (with 32 bobbins). The new model MULTIMATIC MM32 was launched during ITMA 2019.

MULTIMATIC is the best solution for high quality warp beams for sample, short and medium warp beam lengths with the following attractive features/benefits:

- Exceptional level of performance in terms of productivity and patterning flexibility

- The first sample warping machine in the world with working width of 2200 mm and 3600 mm

- Depending on yarn quality and density of the warps, MM 128 can produce maximum lengths up to 1,500 mtr and MM 32 can produce 1,050 mtr

- Bobbins are mounted in the standard H or parallel creel respectively

- The warp colour selection is done automatically as per the set patterns with the top production speed and high-precision yarn laying on revolving drum of 7.0 m circumference

- Yarns are positioned as per selection with high accuracy and at a maximum warping speed of 800 m/min

- The warps are characterised by a uniform beam wind, constant yarn tension levels and high-precision yarn laying

- The high precision yarn-laying devices are also used for leasing of the dividing cords without affecting the working speed

- The yarn feed belt can operate at different speeds and can be adapted to different yarn densities, counts as per the pattern requirements

- Minimal wastage – yarns which do not run on the warping drum as they are not needed in the patterns are taken off by the patented central cord and held under tension, resulting in the minimal wastage of yarns

- The possibility of processing pattern repeats via CAD systems and office computer during production minimises the setting-up time

- The most efficient KARL MAYER Teleservice support is available for quick technical support and guidance

MULTIMATIC – some key highlights:

- Quick execution of work

- Productivity with low number of packages

- Yarn optimisation and waste reduction

- Better operating behaviour of the warp in the weaving machine

- Manpower saving as it hardly need operator intervention

- Highest quality warp beams assured

With excellent features and benefits, the ROI with MULTIMATIC has proven to be much more attractive compared to any other technology in this field. KARL MAYER has installed more than 60 MULTIMATIC machines across the world, mainly in Europe. In India, the first MULTIMATIC 128 machine was installed at the world renowned home furnishing maker D Décor. The experienced sales team of A.T.E. Enterprises Private Limited, the sole selling agent of KARL MAYER in India, together with KARL MAYER, can support customers in analysing their products needs and can offer the best suited solutions to meet customers’ production and pattern warping needs.