The world’s leading textile and garment technology exhibition, ITMA 2019 is gearing up for another vibrant showcase of the latest trends, technologies and materials. The show will be held from 20 to 26 June at Fira de Barcelona, Gran Via venue. The exhibition will feature over 1,600 exhibitors who will be showcasing their latest technologies and sustainable solutions for the entire textile and garment manufacturing value chain, as well as fibres, yarns and fabrics.

“The response for ITMA 2019 is so overwhelming that we have not been able to meet the demand for space despite adding two more exhibition halls. ITMA is a show for the industry, by the industry. Hence, we are of the opinion that ITMA should feature a wide spectrum of cutting-edge solutions from as many solutions providers as possible, whether established or new-to-market,” says Fritz P Mayer, President of CEMATEX.

Charles Beauduin, Chairman of ITMA Services, which organises ITMA 2019, elaborated, “As an international platform, our priority is to accommodate as many eligible applicants as possible to participate in the exhibition. It is heartening that the CEMATEX associations are supportive of this approach. Currently, we were only able to accommodate some 1,660 exhibitors from 47 countries on the show floor.”

Federico Pellegata, Director of ACIMIT (Association of Italian Textile Machinery Manufacturers), commented, “We understand the space constraints and appreciate that the organising team’s priority is to try to maximise the admission of companies so that ITMA 2019 can be a more vibrant and trendsetting platform that will benefit the entire industry.”

One of the top sectors in terms of space applied is spinning. An exciting sector at ITMA 2019 is printing. Previously part of the finishing sector, printing as a standalone chapter has garnered very strong interest as the industry embraces digital transformation. The number of exhibitors in the printing and inks sector has jumped some 30 per cent from ITMA 2015.

Besides printing, another sector that is undergoing vast transformation and rapid development is the garment making sector. Previously labour intensive, the garment industry now sees a gamut of solutions utilising artificial intelligence, robotics, vision systems and other advanced automation.

Besides, ITMA 2019 will demonstrate the ‘inventive DNA’ of Switzerland’s machinery producers For textile machinery manufacturers and their customers, ITMA is the ‘greatest show on earth’ – attracting huge numbers of delegates eager to discover the latest technology trends and the newest machinery developments.

The 2019 edition of this four-yearly event takes place in Barcelona in June, and there will again be a strong presence of Swiss textile machinery companies, whose participation at any ITMA is always the focus of enormous visitor interest. The majority of the 63 exhibitors from Switzerland at ITMA 2019 will attend under the organisation of their national representative body, the Swiss Textile Machinery Association (Swissmem), whose President, Ernesto Maurer, promises an exciting and dynamic showcase of genuine innovation, “Swiss machinery manufacturers always provide some of the headline presentations at the big exhibitions,” he says.

“Barcelona this year will be no exception, as our members will certainly demonstrate the power of Swiss innovation, a tradition rooted in our national DNA across numerous groundbreaking inventions in textiles and the wider world.” At ITMA every major sector along the textile value chain will be covered by Swiss exhibits, ranging from fibre and yarn manufacturing through knitting, weaving, nonwovens, dyeing and finishing. In many of these disciplines, such as textile testing and quality control and yarn spinning, Swiss firms lead the world. Tradition provides the essential background to the Swiss innovative spirit, but progress today sees companies which are in the forefront of modern and future trends in areas such as digitalisation, sustainability and energy efficiency, with data handling and interpretation underpinning practically every aspect of their work.

As the textile and garment industry trends towards an integrated manufacturing value chain, many new-to-ITMA solutions providers have been attracted to take part in ITMA 2019; some of them have chosen to co-locate their booths with their industry partners to offer integrated solutions to buyers. Among the new applicants are Borsoi, Bullmer, Card Clothing & Services, Han’s Yueming Laser, Juki, Serkon Tekstil and SoftWear Automation. Successful ITMA 2019 applicants will be receiving their certificate of admission and details of their booth space this month. The show will now occupy all nine exhibition halls at Fira de Barcelona, Gran Via venue. As a result of the expansion, changes have been made to the

sector allocation plan.

ITMA 2019 forums draw strong industry support

ITMA 2019, will be complemented by several key forums, two of which are the ITMA-EDANA Nonwovens Forum and Textile Colourant and Chemical Leaders Forum. Fritz Mayer, President of CEMATEX, said: “As technological developments are happening at breakneck speed, and collaboration is becoming increasingly necessary in a globalised economy, the industry has to stay abreast of the latest developments and trends. Hence, ITMA will be staging several forums to help participants be ahead of the competition curve.

“The forums also offer a valuable platform for various associations and professionals to connect and network with the right players. This is especially important as collaboration and partnerships from research institutions to technology, chemical and raw material providers and users are increasingly more critical to business success.”

“The forums also offer a valuable platform for various associations and professionals to connect and network with the right players. This is especially important as collaboration and partnerships from research institutions to technology, chemical and raw material providers and users are increasingly more critical to business success.”

ITMA-EDANA Nonwovens Forum: The Nonwovens Forum is jointly organised by ITMA and EDANA. To be held on 21 June 2019, it will highlight the latest innovations in nonwovens. The theme of the forum is ‘Nonwovens Manufacturing Processes for the 21st Century: More Flexible, More Efficient, More Sustainable’. Providing the latest industry insights will be keynote speaker David Allan, Editor, Nonwovens, RISI (United States). His presentation is titled ‘Global Trends in Nonwoven Processes under Economic and Sustainability Constraints’. The forum will feature three sessions:

• Circular economy/challenges & opportunities for processing bio-based & recycled materials on nonwovens machinery

• Latest trends and innovation in nonwoven processes – including hybrids and composites

• Innovations in nonwovens technology.

In addition, there will be a panel discussion with experts from leading centres of excellence in nonwovens who will exchange their views on the nonwoven processes of the 2030s.

Textile Colourant and Chemical Leaders Forum: The 3rd Textile Colourant and Chemical Leaders Forum @ ITMA 2019 on 23 June will focus on the circular economy and resource sustainability strategy and how innovation will drive future industry success. Launched at ITMA 2011, the forum, is an industry initiative that draws lively participation from dyestuff, colour and chemical professionals from around the world. Themed ‘Meeting Resource Challenges in the Circular Economy’, the 2019 forum explores how textile chemicals and innovative and cleaner technologies can help create a more sustainable future for the textile and garment industry. Presentations at the forum are clustered into three sessions:

• Resource management and Industry 4.0

• Responding to sustainability challenges with innovation

• Envisioning the future of the colourant and chemical industry

Chairing the forum is Andrew Filarowski, Technical Director of Society of Dyers and Colourists.

Speakers confirmed for the forum include Christina Raab, Global Implementation Director of The ZDHC Foundation. She will speak on the role of chemistry for circularity in textile, leather and fibre production. She will also elaborate on ZDHC’s approach and tools to drive the transition and uptake of safer and more circular chemistry, as well as the current state and findings of circular implementation projects from the sector.

Another speaker is Dunja Drmac, Sustainability Officer of the European Apparel and Textile Confederation (EURATEX). Her presentation will enlighten participants on resource sustainability and relevant strategies in the journey towards a circular economy.

In addition to the forums, other knowledge sharing activities include the ITMA Innovation Lab. An important element of the lab is the ITMA Speakers Platform where all ITMA exhibitors have been invited to participate.

In next few pages we are covering some of the latest

technologies that will be on display during the show. In the

next edition of Home Textile Views, we will be covering

remaining technologies alongwith ITMA post show report….

ITMA 2019 –TECHNOLOGY PREVIEW

Vandewiele to present carpet weaving machines

Vandewiele is set to present a wide range of technologies, including the latest RCE2+digital carpet weaving machine at ITMA 2019 expo, in hall 4, at stand A206. Vandewiele develops textile systems for flooring qualities, home linen, and fashion fabrics. The company’s sensors, software programmes and servers have become increasingly sophisticated as part of the TEXconnectprogramme, and the real-time data from different machines – across connected manufacturing sites and across different countries and even continents – can be collected and shared. Digital models of both machines and production processes can be created and analysed for the optimisation of production settings, to vastly improve scheduling and planning and also make considerable savings in raw materials and energy consumption. Virtual and remote control now allows for the Big Data analysis that is propelling the industry forward and will pave the way for AI applications. For carpet manufacturers, all of this is leading to the creation of truly Smart Factories, the company said in a report.

Vandewiele is set to present a wide range of technologies, including the latest RCE2+digital carpet weaving machine at ITMA 2019 expo, in hall 4, at stand A206. Vandewiele develops textile systems for flooring qualities, home linen, and fashion fabrics. The company’s sensors, software programmes and servers have become increasingly sophisticated as part of the TEXconnectprogramme, and the real-time data from different machines – across connected manufacturing sites and across different countries and even continents – can be collected and shared. Digital models of both machines and production processes can be created and analysed for the optimisation of production settings, to vastly improve scheduling and planning and also make considerable savings in raw materials and energy consumption. Virtual and remote control now allows for the Big Data analysis that is propelling the industry forward and will pave the way for AI applications. For carpet manufacturers, all of this is leading to the creation of truly Smart Factories, the company said in a report.

The new RCE2+ Rug and Carpet Expert weaving machine is a truly digital workhorse, with all yarns continuously controlled and measured and the difficult bobbin changes of the past completely eliminated. This is as a result of Vandewiele’s latest Fast Creel, with the feed and tension of each pile yarn controlled by individual servomotors. The pile yarns are now fed directly into the machine without having to pass pile-stop motions, to both increase efficiency and eliminate any waste yarns, while achieving previously unreachable industrial speeds. TEXconnect further provides readily-available data on all yarn consumption, tension and threading, and then will supply the predictive maintenance that is paving the way to self-learning carpet weaving machines. The company will also display the INCA (interlacing by non-continuous air) system for BCF extrusion systems – a new method for intermingling BCF yarns which greatly improves tangle knot uniformity for significant cost savings.

The new VSi32 Velvet Smart Innovator jacquard, in combination with the latest Smart Creel, for the production of Italian velvet – combining the potential of flat woven jacquard fabrics with pile yarns leading to the potential for the creation of whole new range of fabrics for the home and for fashion, will also be a part of the show. Vandewiele will present the latest Superba MCD/3 space-dyeing machine, which is capable of handling a layer of 72 ends with an unequalled range of spot length, especially for ultra-short spots of below 25mm. The Vandewiele Cobble Colortec L+, which is now the most versatile tufting machine available on the market, will be present at ITMA 2019, along with a range of jacquards from VandewieleBonas, demonstrated across ITMA 2019 above flat weaving machines from the industry leaders, as well as Vandewiele’s own RCE2+.

The company will display the completely revised Titan 5540 carpet finishing machine from Vandewiele Titan, which is now able to accommodate carpets with straight, round and complexly-shaped corners simultaneously, along with the VandewieleArraycam 5420 optical inspection system which is suitable for monitoring standard fabrics on all common tricot warp knitting machines and the latest IRO-ROJ weft insertion technologies.

New scanning printing systems and Flagship solutions by Aleph

Innovation and environmental sustainability in digital textile printing will be central to Aleph’s showcase at ITMA 2019. A leading Italian manufacturer of sublimation and direct-tofabric inkjet printers for the textile and visual communication industries, headquartered in the textile district of Como, Aleph will unveil a range of brand-new scanning printing systems aimed at enhancing and integrating its flagship series, LaForte. Designed as a fashion boutique, the company’s booth (Hall H3, Stand B131) will host the latest cutting-edge technologies developed by Aleph and a wealth of textile applications, including textiles printed with modern and trendy patterns and designs, aiming to demonstrate how advanced digital printing technologies are transforming the high-end fashion, fast fashion, sportswear and athleisure, home textile industries.

Innovation and environmental sustainability in digital textile printing will be central to Aleph’s showcase at ITMA 2019. A leading Italian manufacturer of sublimation and direct-tofabric inkjet printers for the textile and visual communication industries, headquartered in the textile district of Como, Aleph will unveil a range of brand-new scanning printing systems aimed at enhancing and integrating its flagship series, LaForte. Designed as a fashion boutique, the company’s booth (Hall H3, Stand B131) will host the latest cutting-edge technologies developed by Aleph and a wealth of textile applications, including textiles printed with modern and trendy patterns and designs, aiming to demonstrate how advanced digital printing technologies are transforming the high-end fashion, fast fashion, sportswear and athleisure, home textile industries.

Three pioneering models from LaForte series will be on display at ITMA 2019: Brand-new, top-of-the-line LaForte 600 Fabric, LaForte 200 Fabric and recently launched, dye-sublimation entry-level printer, LaForte 100. “We are excited to be at ITMA 2019 and will use the show to highlight the company’s evolution over the last four years. Not only have we boosted our range of high-performing digital print solutions – which also reflects in the theme and size of our booth – but we have also experienced a continuous corporate growth, up to 50 per cent, following the joint venture with Italian private equity firm, Wise sgr,” comments Alessandro Manes, CEO at Aleph. “Since the official launch of LaForte project, back in 2015, our R&D team has been working hard to improve and consolidate the series. We decided to keep our focus on developing the digital print scanning technology, which can now deliver high volumes, top printed quality and lower production costs, while we consider single pass print technology still at an early stage of its evolution. Furthermore, we have also focused on boosting our workflow software, enhancing our pigment inks and creating complete lines for printing on fabrics, through both the development of proprietary pre and post-press systems and strategic partnerships.”

LaForte series, ranging from entry-level to flagship models

Debuting worldwide at ITMA 2019, LaForte 600 Fabric is an industrial inkjet direct-to-textile printer designed to deliver highvolume manufacturing of extremely high-quality printed textiles. Enabling a print speed from 600 up to 1000 sqmtr/hour at a print resolution up to 1200 dpi, LaForte 600 Fabric almost reaches the same productivity as single-pass inkjet presses but featuring scanning technology. Aleph’s printer features a compact design, which facilitates its integration into various production environments, and a waterless process that reduces the consumption of water and energy, resulting in drastically lowered production costs and environmental impact.

At ITMA, Aleph will exhibit a complete production line, featuring: A fabric feeding system that supports jumbo reels (up to 1 m roll diameter and 1.000 kg roll weight), LaForte 600 Fabric (equipped with 48 printheads), a proprietary drying system and a exit plater including optional winding unit. Both the feeding system and the plater are from Italian company Bianco Group, partnering with Aleph.

Aleph will also use ITMA 2019 to showcase its flagship solutions addressing different textile market segments. These include:

• LaForte 200 Fabric, a direct-to-fabric inkjet printer featuring a compact design and a patented rotary belt. The printer is designed to address mid to high print volume production (up to 400 sqm/h with 3400 mm print width in one pass and up to 300 sqm/h with 1800 mm print width in one pass). At the show in Barcelona, Aleph will showcase a LaForte 200 Fabric model equipped with 8 dual-module printheads (dual channel, two colours per head) and with pigment inks, and will run live demonstrations of direct printing onto wide ranges of fibres.

• LaForte 100 Paper is a versatile inkjet printing system. A water-based dye-sublimation entry-level solution with production speed up to 200 sqm/h, LaForte 100 features 4 to 8 printheads (a 4-printhead model will be displayed at ITMA) and is equipped with a patented rotary belt with vacuum system, which enables to print on paper with grammage starting from 10 gsm. Offering robustness and stability in production, LaForte 100 is designed to deliver high-quality print and addresses those large format printing companies aiming to diversify their product portfolio and to explore new market segments. The printer is suitable for the fast fashion and sportswear market segments, as well as the out of home and soft signage industries.

Another highlight at Aleph’s boutique at ITMA will be the showcase of high-quality printed fabrics and textiles. The brandnew advanced pigment inks and direct disperse dyes developed by Aleph don’t require pre and post treatments – enabling a significant reduction in water consumption – and guarantee durability and colour vibrancy thanks to an innovative binder with ultra-clinging-to-the-fibre capability. In addition, Aleph has recently developed new pre and post treatment solutions that help further enhance the solidity and colour vibrancy also on special fibres.

“ITMA 2019 represents a fantastic opportunity to showcase our cutting-edge technologies in digital textile printing to a global audience. The show in Barcelona will also make an ideal platform to demonstrate how Aleph has succeeded in establishing itself as a leading player in different digital textile printing market segments,” Manes continues. “Aleph is growing fast and internationally, currently counting on an installed base of about 60 LaForte units worldwide. Also, our customers are satisfied with the production performances and the quality of our printers and with the aftersales service that we provide. All in all, we strongly believe that Aleph is set to mark yet another significant landmark in the company evolution at ITMA 2019.”

Mayer & Cie to display new mattress machine

At this year’s ITMA 2019 expo, Mayer & Cie is presenting its new OVJA 2.4 EM mattress machine, in hall H 8.0, booth C 204. Fully electronic, it produces up to 30 kilogrammes of fabric per hour, which makes it the most productive machine of its kind in the world. It is easy to use and can produce a variety of patterns.

At this year’s ITMA 2019 expo, Mayer & Cie is presenting its new OVJA 2.4 EM mattress machine, in hall H 8.0, booth C 204. Fully electronic, it produces up to 30 kilogrammes of fabric per hour, which makes it the most productive machine of its kind in the world. It is easy to use and can produce a variety of patterns.

The OVJA 2.4 EM is a new Mayer & Cie development that is specially geared to recent changing requirements in the manufacture of mattress cover fabrics. Its focus is on maximising output, which it achieves by means of a combination of a larger number of knitting systems and a higher rotation speed, Mayer & Cie said.

In addition to high productivity the OVJA 2.4 EM’s impressive features include ease of use and a wide range of patterns. The horizontal weft yarn guide on each cylinder segment ensures even, easy operation, short changeover times and a high level of reliability. Thanks to the improved thread guide and the air-controlled thread fluctuation control system the thread tension remains constant even at high speeds. That keeps thread vibration to a minimum and the thread is transported safely to the needles. Despite the high productivity the especially gentle needle guidance ensures an unusually low level of needle wear and tear. At the same time the OVJA 2.4 EM offers a wide range of designs that can be changed very quickly thanks to electronic single needle selection in the cylinder.

The most important markets for Mayer & Cie. in this segment are Belgium and the US, but Mayer & Cie machines also make mattress cover fabrics in Italy, Turkey and Asia, especially China and Indonesia. For the production of high-quality mattress cover fabrics Mayer &Cie has a range of purposebuilt machines. Pattern variety, ease of use and productivity are the key factors. Mattress patterns are among the most complicated that are manufactured and the fully electronic circular knitting machines in Mayer & Cie’s OVJA range deliver precisely these benefits. In the OVJA 2.4 EM, Mayer &Cie now presents a mattress machine that outperforms all previous machines in its segment for productivity, is decidedly userfriendly with a wide range of patterns.

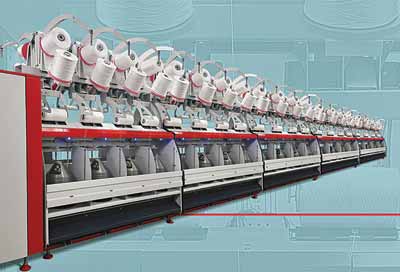

Twisting solutions for carpet yarns, ropes, twines and threads by Meera

Meera Industries Limited will exhibit its range of innovative twisting Machines for carpet Yarns, Ropes, Twines and Thread in Hall No. 6, Stall No. C204. Having a customer centric approach MEERA’s main designing principal has always been Energy optimization, High Productivity and Ease of Use. MEERA will exhibit below machines at the ITMA 2019.

Meera Industries Limited will exhibit its range of innovative twisting Machines for carpet Yarns, Ropes, Twines and Thread in Hall No. 6, Stall No. C204. Having a customer centric approach MEERA’s main designing principal has always been Energy optimization, High Productivity and Ease of Use. MEERA will exhibit below machines at the ITMA 2019.

Carpet Cabler / Carpet Twister is a heavy-duty direct cabling / Twisting machine with sturdy structure designed to produce premium quality yarns for carpet at most economical cost. Having a Denier Range of 1200-12000, this Twister / Cabler is suitable for all types of BCF (Bulk Continuous Filament) and Textured yarns like PP, Polyester, Nylon. Energy conservation, High Productivity and Ease of Use are the principal in mind when we designed Direct Cabler CK-260. The machine is loaded with several features which add to high productivity, better production management through advanced reporting through smart quality control and software solutions. CK-260 is highly efficient, economical and easy to operate cabling machine comparable to similar offerings from European markets. The company is highly optimistic for its success during the ITMA 2019.

TPRS is a One Step Ply and Cable Twisting Machine

MEERA being pioneer of TPRS technology is proud to exhibit this machine at the show. TPRS is also known as One Step Twine Twister for Cotton, Polyester Nylon, PP for denier upto25,000. Traditionally Ply and Cabling Process took 3 Steps, through TPRS technology the same Twine can now be made in just in One step. Twisting up to 4 Ply and denier range from 3,000-25,000, TPRS is available in three different models, TPRS-19, TPRS-25 and TPRS-50. Over all costing of producing S/Z yarns through TPRS is 40 per cent less compared to traditional methods. Easy to Use, Highly Efficient TPRS has proven to be a boon for Fish Net Yarns, stitch thread, carpet yarn, industrial thread, PP mouth closing thread, ropes and twines, raffia etc.

Ring Twister: The Third machine at the show for making technical yarns like Glass, Dyneema, Carbon and Ropes, Cotton Twines, Rafia Twines, Mop Yarns, Artificial Grass, upto 6 mm etc. Meera’s Ring Twister is a high speed Fully Automatic Twisting Machine with Precise Ring Rail Control, Pneumatic Pressurised Yarn Feeding, and Individual Spindle Drive Motor available in Various Ring Size from 140 – 300 mm. MEERA is planning to demonstrate twisting of MOP Yarns, Glass yarns and Raffia during the show.

Stäubli exhibits Weaving and Knitting Solutions

At this year’s ITMA in Barcelona, Stäubli will be showing a selection of its latest products from its extensive range. Many machines will be displayed in operation at two separate booths: Weaving solutions at booth C201 in Hall 4, Knitting solutions at booth B212 in Hall 8.1.

At this year’s ITMA in Barcelona, Stäubli will be showing a selection of its latest products from its extensive range. Many machines will be displayed in operation at two separate booths: Weaving solutions at booth C201 in Hall 4, Knitting solutions at booth B212 in Hall 8.1.

With core competencies in shedding (cam motions, dobbies, and Jacquard machines) and weaving preparation (drawingin, leasing, and warp-tying machines) Stäubli plays an important role in the design and quality of woven end-products. Based on over a century of experience in the traditional textile industry and its continuous R&D activities, Stäubli constantly offers new and improved high-performance systems and solutions for processing fabrics for fashion, home textiles, automotive, protection, carpeting, and highly complex technical textiles.Visitors to the booths will learn how Stäubli solutions can boost their weaving performance and overall mill efficiency. Besides offering many decisive functional advantages, the machines promise maximum service life.

SAFIR S60 automatic drawing-in system with Active warp control features: The SAFIR series of drawing-in systems offers unique advantages thanks to AWC (Active Warp Control), Stäubli’s exclusive yarn-repeat management system. Visitors to the booth will quickly see how the precision of this ingenious technology leads to more first-quality output, supports on-time delivery, and boosts the overall productivity of the weaving department.

LXXL Jacquard machine featuring a revolutionary electronic concept: The LXXL machine boasts a large format (up to 25,600 hooks, or 51,200 hooks in a tandem installation), completing the full range of LX/LXL series machines for flat, terry, and velvet fabrics. All the machines in this series feature lifting motions that ensure precise shedding geometry and absolutely vibration-free movement even at high speeds. The optimally coordinated kinematics of all moving parts within the machines and the directly mounted components such as the drives enable routine weaving of very heavy fabrics. Stäubli recently developed a revolutionary electronic concept that perfectly integrates the constraints of high-speed weaving and the significant number of hooks to be lifted.

LX32 Jacquard machine for narrow fabrics and labels

Stäubli’s broad range of Jacquard solutions includes the LX12/ 32/62 models for producing narrow fabrics such as ribbons and labels. These machines are versatile, easy to adapt, and allow optimal location in relation to the perforated board – all of which enhances the quality of narrow fabrics. Available for all types of needle looms, this series enables high-speed weaving and promises long-lasting performance.

Atlas displays its latest colour fastness instruments

For more than 100 years, Atlas has been a leader in mate rials durability testing, offering a complete line of weathering testing instrumentation, laboratory, and outdoor testing services. Atlas products are designed and manufactured to conform to international and industry standard test methods, including ISO, ASTM, DIN, JIS and numerous others. Markets include automotive, paint and coatings, plastics and additives, textiles, pharmaceutical and consumer products, architecture, aerospace, photovoltaics, and packaging.

For more than 100 years, Atlas has been a leader in mate rials durability testing, offering a complete line of weathering testing instrumentation, laboratory, and outdoor testing services. Atlas products are designed and manufactured to conform to international and industry standard test methods, including ISO, ASTM, DIN, JIS and numerous others. Markets include automotive, paint and coatings, plastics and additives, textiles, pharmaceutical and consumer products, architecture, aerospace, photovoltaics, and packaging.

Atlas is a business unit of AMETEK Measurement, Communications & Testing, a Division within AMETEK’s Electronic Instruments Group, a recognized leader in advanced monitoring, testing, calibrating and display instruments. AMETEK, Inc. is a global leader in electronic instruments and electromechanical devices. Atlas Material Testing Solutions, a global leader in accelerated light fastness testing equipment for the textile industry, will showcase its Ci3000+ and Xenotest® 440 instruments at ITMA 2019.

The Ci3000+ is recognized as the standard instrument globally for textile testing. With its advanced digital control system and optical technologies, the Ci3000+ delivers exceptionally precise and reliable control of all test parameters to accurately predict service life. The two-tier rack option provides a 50 per cent increase in capacity and a large graphic user interface allows for intuitive operation. It meets all primary internationally recognized standards for textile lightfastness, including AATCC, ISO, Marks & Spencer, and GB/T.

The Xenotest 440 sets the standard in economical, mid-sized, air-cooled xenon devices, with an array of options to meet global weathering and light fastness testing requirements. Combining a highly efficient design – including ultrasonic humidifiers to reduce water consumption – and XenoLogic™ twin-lamp technology, which enables high irradiance levels to significantly reduce test times. It is ideal for meeting common lightfastness standards such as ISO 105-B02, AATCC TM 16.3 and ASTM G155.

SPGPrints to display new textile printing machines

SPGPrints is set to display new, inno vative textile printing machinery at ITMA 2019, in hall 3, stand B203. SPGPrints, headquartered in Netherlands, is the global leading provider of integrated solutions for textile, label, and industrial markets. For printing companies who are ready to embark on a digital textile printing journey, a visit to ITMA Barcelona 2019 will definitely be worthwhile. SPGPrints will be giving live demonstrations of its second generation Pike single-pass digital textile printing machine printing on viscose fabric with reactive inks. Based on the Pike’s established image quality performance combining the industry’s highest resolution of 1200 dpi with the smallest droplets and lowest ink consumption, visitors at ITMA can see the new Pike printing at considerably higher speeds than before while producing the best deep black blotches ever created in the industry, the company said.

SPGPrints is set to display new, inno vative textile printing machinery at ITMA 2019, in hall 3, stand B203. SPGPrints, headquartered in Netherlands, is the global leading provider of integrated solutions for textile, label, and industrial markets. For printing companies who are ready to embark on a digital textile printing journey, a visit to ITMA Barcelona 2019 will definitely be worthwhile. SPGPrints will be giving live demonstrations of its second generation Pike single-pass digital textile printing machine printing on viscose fabric with reactive inks. Based on the Pike’s established image quality performance combining the industry’s highest resolution of 1200 dpi with the smallest droplets and lowest ink consumption, visitors at ITMA can see the new Pike printing at considerably higher speeds than before while producing the best deep black blotches ever created in the industry, the company said.

Also, from the established Javelin multipass printing machine, a second generation will be showcased at ITMA 2019. Besides the extension with an acid and a direct sublimation application, this new Javelin will have additional functionality that boosts both the top printing speed as well as the average speed to print every design, resulting in a higher print capacity per day or month.

Visitors wanting to learn more about the company’s world-renowned consumables can visit the unique Experience Centre at their stand. In the Digital Ink Experience Centre, SPGPrints will take the visitors behind the scenes of the development and production of their high-quality digital inks and launch two new versions of their deep black ultra HD in the Nebula reactive ink series for Kyocera print heads.

In terms of conventional printing systems, SPGPrints will take the opportunity to showcase its latest generation of the nine colour Pegasus EVO rotary screen printing machine at ITMA 2019. Visitors can learn about the innovative construction and technology and learn how both the Pegasus EVO as well as their RD8 rotary screen printing machines can help them enhance their printing process. The company will be launching two of its latest, most innovative screen technologies, the new Ortascreen and the new Randomscreen Eco, at the Screens Experience Centre at ITMA 2019.

In the Screens Experience Centre, visitors can learn more about which screen type helps them create the best output. At the Screens Experience Centre, SPGPrints will give the opportunity to actually see, hear, and experience why their rotary screens are unique in its kind and the visitors can see and touch its highquality output.

High-quality printing output starts with selecting the excellent screens. But a good screen is useless when it’s engraved in a bad way. The BestLEN direct laser engraving machine is the benchmark equipment for engraving high-quality screens for textile printing process. At ITMA 2019, visitors will be able to see the BestLEN direct laser engraving machine and learn about the different engraving techniques.

With hundreds of BestLEN engravers currently being operated, the direct laser engraving machine helps printing companies worldwide to produce a consistent level of high-quality screens with minimum interference of their operators. Since the BestLEN has a dry process, a minimum amount of water is used and the engraving process is very short, while human interference is brought back to a minimum.

Mimaki presents printing machine and pre & post treatmnet machines

Mimaki is a leading manufacturer of wide-format inkjet printers and cutting machines for the sign/graphics, industrial and textile/apparel markets. Mimaki develops the complete product range for each group; hardware, software and the associated consumable items, such as inks and cutting blades. The company excels in offering innovative, high quality and high reliability products, based upon its aqueous, latex, solvent and UVcurable inkjet technology. In order to meet a wide range of applications in the market, Mimaki pursues the development of advanced on-demand digital printing solutions. Mimaki Engineering Co. Ltd., Nagano (Japan), is publicly listed on the Tokyo Stock Exchange, Inc. Mimaki Europe will be showcasing the Tiger-1800B MkII and the TR Series at ITMA 2019, Hall 3, Stand B110.

Mimaki is a leading manufacturer of wide-format inkjet printers and cutting machines for the sign/graphics, industrial and textile/apparel markets. Mimaki develops the complete product range for each group; hardware, software and the associated consumable items, such as inks and cutting blades. The company excels in offering innovative, high quality and high reliability products, based upon its aqueous, latex, solvent and UVcurable inkjet technology. In order to meet a wide range of applications in the market, Mimaki pursues the development of advanced on-demand digital printing solutions. Mimaki Engineering Co. Ltd., Nagano (Japan), is publicly listed on the Tokyo Stock Exchange, Inc. Mimaki Europe will be showcasing the Tiger-1800B MkII and the TR Series at ITMA 2019, Hall 3, Stand B110.

TR series Rimslow Series – A complete line of textile pre-treatment and post-treatment machines

With this one-stop solution for coating, printing, steaming and washing machines, companies in the textile industry now have complete control over their production process. Customers have a single point of contact for all support for their textile production process, allow-ing them to save a lot of time, effort and money. This is how you really make use of all the advantages of digital textile printing.

• Choose the set that benefits you the most

• Ink and corresponding pre-treatment machine for consistent results

• Colouring test before the production run

• One-stop source for your textile production

Belt-Type Inkjet Printer High Speed range Model – Tiger-1800B MkII

• Selectable print mode to suit the production (from high-speed to highquality)

– Maximum print speeds of up to 385 m2/h in high-speed mode.

– For the realization of higher quality of print, 1,200 dpi print mode is added and the multi-pass is applied

• Mimaki Advanced Pass System (MAPS) delivers stable high-quality printing

• Droplet print mode selection suitable for print data: Depending on ink type and printing mode, there are 4 different

droplet sizes. Droplet print mode can be choose to match the print data from high speed and standard mode

• Nozzle recovery system (NRS): Consecutive operating solution to maintains the productivity (* NRS is to be applied from December 2018.)

• Stable and reliable mechanism secures high-speed printing

– Stable textile transportation mechanism (Twin pressure roller shafts, Jam sensor, Wrinkle sensor)

– Degassing module and ink circulation mechanism maintain optimum ink conditions

– Automatic wiper cleaning

• Extensive optional units for accommodating various applications: Extensive lineup of optional devices to be selected

according to the type and status of fabric and transfer paper, including the storage after printing

• Large-sized ink tank (10 kg) ensures costeffective print operation: The bulk ink supply enables effective long-hour printing while reducing the operational cost

• High-performance software RIP “TxLink3 Standard”: The TxLink3 Standard offers simple RGB and CMYK color replacement on raster and vector data, as well as the ability to produce different colour patterns

Homer presents high speed digital belt-conveying printer

Shenzhen HOMER Textile Tech Co., Ltd was established in 2012 and became a wholly-owned subsidiary of Hanglory Group in 2015. A state-level high-tech enterprise, Homer Textile has always been focusing on R&D, manufacturing, sales and service of digital textile printers. During ITMA’s 7-day exhibition, you will witness the innovative printing technology of 3 digital textile printers, HM1800R, HM3200R and HM1800B—K32. HM1800B-K32 is the latest ultra-high-speed digital belt-conveying printer that HOMER Digital will launch at ITMA 2019. Based on the previous digital belt-conveyor printing models, it has made a lot of technological innovation. Below is a brief introduction to the main features of HM1800B-K32.

Shenzhen HOMER Textile Tech Co., Ltd was established in 2012 and became a wholly-owned subsidiary of Hanglory Group in 2015. A state-level high-tech enterprise, Homer Textile has always been focusing on R&D, manufacturing, sales and service of digital textile printers. During ITMA’s 7-day exhibition, you will witness the innovative printing technology of 3 digital textile printers, HM1800R, HM3200R and HM1800B—K32. HM1800B-K32 is the latest ultra-high-speed digital belt-conveying printer that HOMER Digital will launch at ITMA 2019. Based on the previous digital belt-conveyor printing models, it has made a lot of technological innovation. Below is a brief introduction to the main features of HM1800B-K32.

HM1800B-K32 – Ultra-high-speed digital belt-conveying printer

Highlights:

• Ultra-high-speed belt continuous conveyor, the max. Productivity up to 900m²/h;

• Equipped with Kyocera nozzles for 1- pass high-resolution printing. The max. resolution is 600 x 2400 dpi;

• Industrial wide-format design with a maximum print width of 1900mm, applicable to materials with various sizes;

• Relying on the strong R&D team of Hanglory Group, HOMER has rich experience in the digital printing industry, as well as stable performance in production;

• Equipped with a high-precision belt conveyor system, the data error during the transmission process can be greatly reduced, and the high degree of reproduction of original images can be better realized;

• With strong after-sales service system, HOMER has a world-wide technical support team, offers 24/7 after-sales service for customers.

HM3200R

• Up to 360 m2/hr Printing Speed

• Symmetrical Colour Alignment

• High-strength steel rail beam

• Anti-scratch printhead protection design

• Industrial ink supply system

• Integrated software control system

HM1800R

• Up to 320 m2/hr Printing Speed

• Symmetrical Color Alignment

• High-strength steel rail beam

• Anti-scratch printhead protection design

• Industrial ink supply system

• Integrated software control system

Kornit presents Single-Step Industrial Solution for Digital Direct-to-Fabric Printing

The innovative technology addresses the growing need for on-demand textile design and production Kornit Digital, a global market leader in digital textile printing innovation, has announced the introduction of the new Kornit Presto, the only industrial single-step solution for direct-to-fabric printing. The Kornit Presto solution eliminates the need for pre and post treatment of fabric and allows for high quality printing on an extraordinarily broad variety of fabric types and applications. The Kornit Presto does not consume water in the printing process, making it the most environmentally friendly solution available for direct-tofabric textile printing today.

The innovative technology addresses the growing need for on-demand textile design and production Kornit Digital, a global market leader in digital textile printing innovation, has announced the introduction of the new Kornit Presto, the only industrial single-step solution for direct-to-fabric printing. The Kornit Presto solution eliminates the need for pre and post treatment of fabric and allows for high quality printing on an extraordinarily broad variety of fabric types and applications. The Kornit Presto does not consume water in the printing process, making it the most environmentally friendly solution available for direct-tofabric textile printing today.

The new Kornit Presto comes with the ground-breaking Neo Pigment Robusto, the best Pigment-based ink available in the industry. Implemented into the renowned Kornit Neo PigmentTM process, the Robusto provides above industry standard wash and rub results and exceptional colour fastness across a wide fabric and application range. The Robusto enjoys faster physical and chemical bonding characteristics, enabling a significantly shorter curing time while providing industry-leading quality and a wide colour gamut. The Neo Pigment Robusto ink was developed with sustainability priorities and is Eco Passport and GOTS V5 approved.

The Kornit Presto solution suits a wide range of business and application needs in a variety of industry segments, including fast growing segments within the ondemand fashion and home décor markets. It is a highly productive solution, available in multiple configurations and able to print 450 sq mtr per hour.

Gart Davis, CEO at Spoonflower, the world’s first web-based service for custom, on-demand fabric and design creation and a long-time Kornit customer, commented, “We were thrilled to be able to test the new system and found the Presto to be in a class by itself; it prints beautifully on all kinds of fabrics, in a single-step, with an environmentally friendly dry process, and now at a multiple of productivity. Its partnership with Kornit continues to be fundamental to its mission to make custom fabric accessible to designers, creative individuals and small businesses all over the world. We can’t wait to get going.”

Kerry King, Senior Vice President of R&D at Spoonflower, added, “The unique integration of the pre-treatment step into the printing process enables a level of efficiency that’s key to our web-toprint business.”

Omer Kulka, Kornit’s VP of Marketing and Product Strategy, also commented, “Kornit is on a mission to reinvent the textile printing industry with gamechanging sustainable technologies for growing market segments. It continues to see demand growth for on-demand production in fashion and home décor. This revolutionary technology is further proof of Kornit’s commitment to address the textile industry’s most urgent needs.”

Epson to display latest digital textile printing innovations

The Japanese company, together with its For.Tex. and F.lli Robustelli subsidiaries, will display the latest digital textile printing innovations and trends at ITMA – the key world exhibition dedicated to digital textile printing. The Japanese pioneer in digital textile printing technology Epson, with its For.Tex and F.lli Robustelli subsidiaries, will display (at Hall 3 – Stand C210) the latest innovations and solutions for the textile market. For.Tex provides dyes, thickeners and products for pre/post treatment of fabrics and F.lli Robustelli is a leading company in the engineering and production of textile printers.

The Japanese company, together with its For.Tex. and F.lli Robustelli subsidiaries, will display the latest digital textile printing innovations and trends at ITMA – the key world exhibition dedicated to digital textile printing. The Japanese pioneer in digital textile printing technology Epson, with its For.Tex and F.lli Robustelli subsidiaries, will display (at Hall 3 – Stand C210) the latest innovations and solutions for the textile market. For.Tex provides dyes, thickeners and products for pre/post treatment of fabrics and F.lli Robustelli is a leading company in the engineering and production of textile printers.

ITMA 2019 will be an opportunity for Epson to show its unique Total Solution, a turnkey, integrated system for the textile printing world. Total Solution helps operators seize digital textile market opportunities. The all-inclusive textile digital printing system features Precision Core printheads which are a state-of-the art textile printing technology. Genesta inks have been developed to offer their maximum results using Epson technology and fabric treatment expertise. This system finds its maximum expression in Monna Lisa series, the successful range of industrial printers and a reference for the high-quality textile printing sector.

At the stand, you will experience stateof- the-art Epson technology for direct to fabric printing and for the sublimation printing. “Our ITMA 2019 presence confirms Epson’s commitment to the continuous high-quality ink and printer development,” states Paolo Crespi, Direct to Fabric Sales & Marketing Director EMEAR & Americas. “Our goal is to become an indispensable technological partner in the high-quality textile printing sector. This includes the DTF market, we developed by launching Monna Lisa together with our partners of excellence F.lli Robustelli and For.Tex. The sublimation solutions where Epson is recognised in every market segment, is part of our complete offer for the printing sector.”

Focus sustainability

The sustainability issue is a focus for market consumers and operators in the textile industry as well as for ITMA, “Innovation for industry sustainability.” Inkjet printing is a sustainable alternative to traditional printing. The advantages are not only financial and organisational but also ecological. Today’s fashion industry is increasingly sensitive to sustainability issues and is finding in digital textile printing a powerful ally, so that an increasing amount of fabrics are printed using this technology.

Twine to launch digital thread dyeing system

Twine Solutions, an Israeli technology start-up, will officially launch its digital thread dyeing system, which dyes raw and off-the-shelf white thread, during live demonstrations at the ITMA 2019 show. Twine’s system digitally dyes white thread from different manufacturers that can be used for a range of applications, such as apparel, activewear, shoes, accessories, home decor, vehicle upholstery and more.

Twine Solutions, an Israeli technology start-up, will officially launch its digital thread dyeing system, which dyes raw and off-the-shelf white thread, during live demonstrations at the ITMA 2019 show. Twine’s system digitally dyes white thread from different manufacturers that can be used for a range of applications, such as apparel, activewear, shoes, accessories, home decor, vehicle upholstery and more.

“Our Twine Digital Thread Dyeing system unleashes the power of thread, at the touch of a button. The fast-paced digital transformation of the textiles industry is challenging both for production and its environmental impact. We are excited to bring solutions that will have much needed and crucial economic, social and sustainability benefits,” commented Alon Moshe, Twine CEO and Co-Founder.

Twine will be exhibiting at Hall 3, where visitors will be able to see the systems digitally dyeing various thread types, in-cluding Coats thread. The strategic partnership between Twine and Coats was announced last November and will include future capabilities of Twine’s system, to feature inbuilt colour software, integrated with Coats ColourStitch. Coats will also be represented on Twine’s booth at ITMA. “This is yet another step in reinforcing the joint work on the future technology for the textiles industry,” the company says.

Twine will also showcase its digital colour matching mobile application. The SnapMatch application captures an image of a sample using a mobile device and Twine’s proprietary algorithms analyse the colour immediately and accurately, according to the company. The user then sends the captured colour to the TS-1800 system for immediate thread dyeing in the desired colour.

Twine’s products create a virtual inventory, with any colour and any length needed, reducing stock management, inventory and deadstock costs. Twine’s sustainable digital waterless thread dyeing process is also said to save 70 litres of clean water per 1 kg of dyed thread.

The process also reduces waste and emissions. “In many of the industry sectors today up to 50 per cent of dyed thread is disposed of before even being used. Twine’s system dyes exactly the amount you need when you need it, in a highly sustainable process,” the company explains. Twine Solutions was founded in 2015 in Israel by brothers Alon and Erez Moshe. It is based in Petah Tikva, near Tel Aviv, an innovation hub for digital printing.

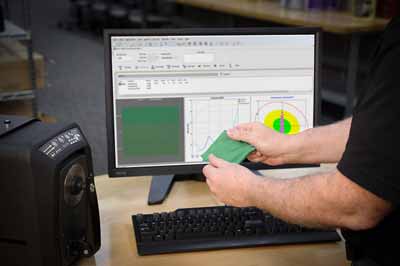

X-Riteshowcases new colour formulation software

X-Rite Incorporated and Pantone LLC, global leaders in color science and technology, announce the availability of its latest release of Color iMatch formulation software for the textile industry. The company will showcase the software at ITMA, June 20 – 26 in Barcelona, Spain. Color iMatch accelerates recipe creation for the textile industry through better initial matches and fewer corrections for faster dyeing times, cost savings and reduced waste.

X-Rite Incorporated and Pantone LLC, global leaders in color science and technology, announce the availability of its latest release of Color iMatch formulation software for the textile industry. The company will showcase the software at ITMA, June 20 – 26 in Barcelona, Spain. Color iMatch accelerates recipe creation for the textile industry through better initial matches and fewer corrections for faster dyeing times, cost savings and reduced waste.

“Today’s apparel and textile manufactures work with a number of natural and synthetic materials as well as a diverse colour palette that can lead to longer colorant recipe creation times and multiple lab dips,” said Richard Knapp, Product Manager, X-Rite and Pantone. “At ITMA, textile suppliers will see how easy it is to access spectral data for a brand’s colour palettes through PantoneLIVE and immediately begin the formulation process in Color iMatch. Attendees will also learn how to dynamically update dye characterizations to significantly improve match performance and meet tight manufacturing deadlines while reducing environmental impact.”

Color match performance in textiles is a function of how accurately dye behaviour in a formula reflects dye behaviour under current conditions and processes. The new release of Color iMatch improves colour matching by addressing this interdependence. It intelligently processes color data to provide optimal initial colour matches and reduce wasteful formulation attempts. With a high return on investment, Color iMatch streamlines complicated textile workflows, improves formulation efficiency, and reduces material waste.

The latest release of Color iMatch offers textile and apparel manufacturers:

• Increases match rate up to 50 per cent and cuts correction steps by more accurately identifying likely dye combinations and accounting for current process conditions

• Ability to dynamically update dye characterizations to maintain dye behaviour, which may shift over time due to variations in ambient conditions, procedures, equipment or materials

• New matching technology to gain insights from historical data and optimize the formulation process

• Fully-integrated Colorant Editor for improved database performance by providing specific guidance that guarantees match prediction confidence

• Digital specification of Pantone standards, including Pantone Fashion, Home + Interiors System for cotton and nylon, through PantoneLIVE™, which provides the official spectral values for Pantone standards

• Easy transition between jobs by applying dynamic Formulation Rules that include process, material and customer specifications

• A gamut viewer to visually evaluate achievability by offering a unique target overlay to help lab professionals make educated formulation decisions

Color iMatch is compatible with current and future Microsoft Operating Systems and offers support for X-Rite and non-XRite instruments.